A Flight Case, also known as a Road Case is a solid container used for transporting equipment that is either valuable or fragile. Flight Cases are primarily associated with their use for transporting audio equipment for large scale music concerts, but they are also widely used in military, medical, audio visual and live broadcast environments.

Flight cases are generally constructed from robust material such as plywood’s or specially designed plastic boards which are held together using aluminium extrusions, steel corners and steel hardware designed to survive frequent heavy impacts.

Flight cases can be custom designed to fit and protect unique objects, but they are also frequently available in standard sizes for common musical instruments.

What is the purpose of Flight Case Hardware?

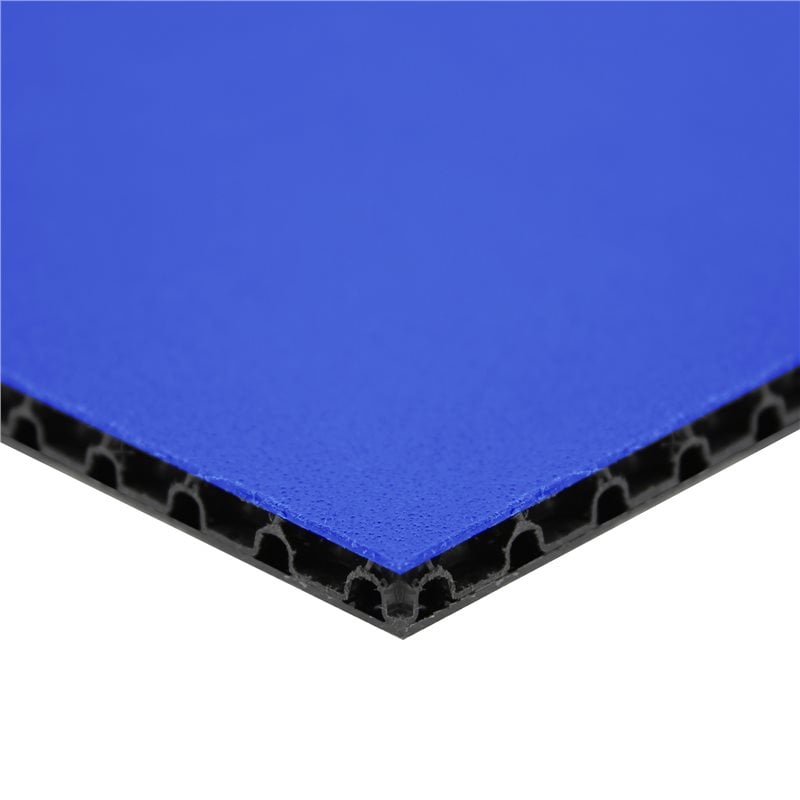

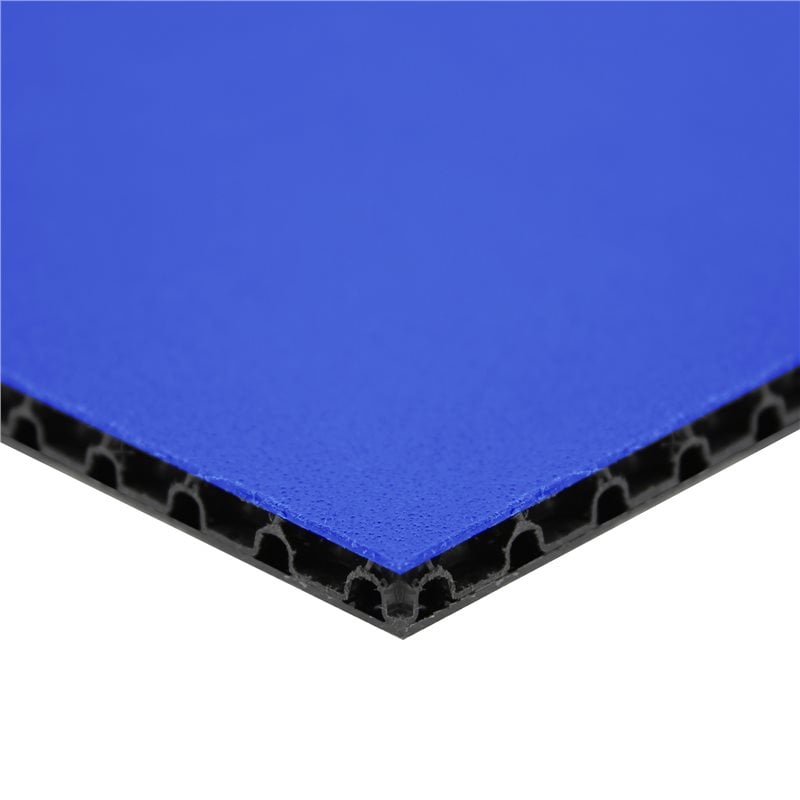

Boards and Panels

Flight case boards are used to build the shape and frame of the case.

Boards and panels can come in various hardwearing materials such as plywood or polypropylene plastic.

Flight case boards and panels come in a large range of colours and many can also be etched, engraved or screen printed with wording or branding.

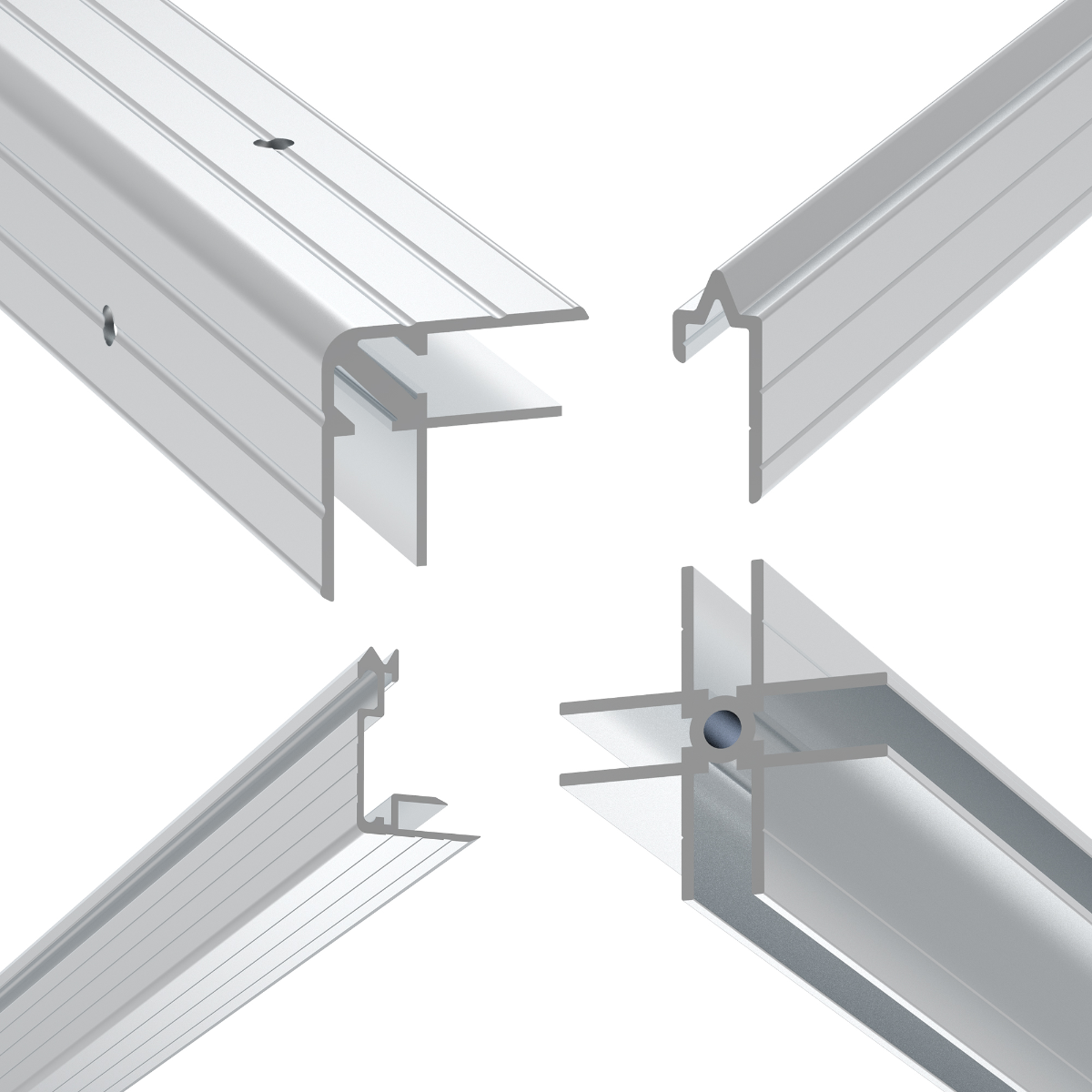

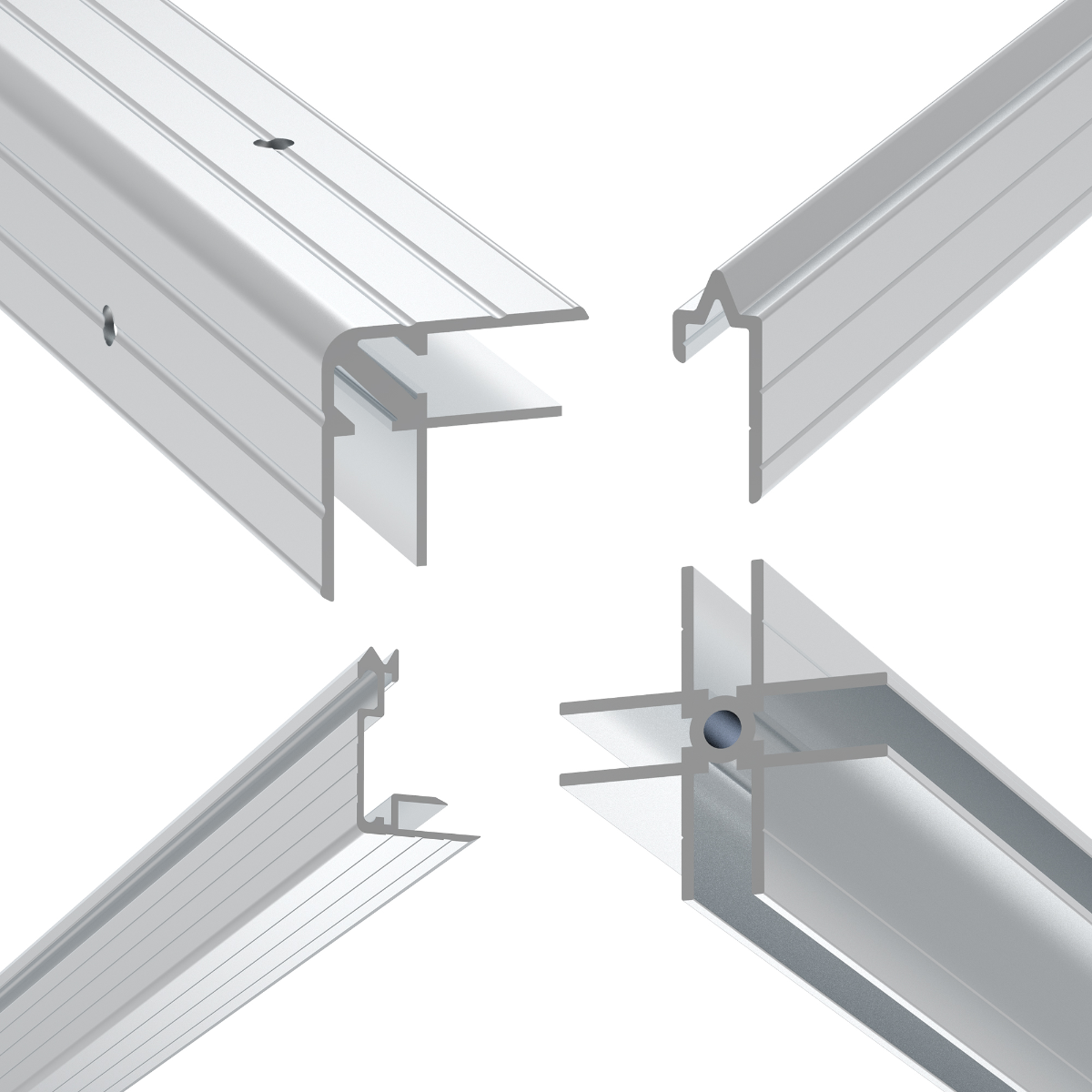

Extrusion

Extrusion is used to fit and attach flight case boards together. Extrusion also protects the case against bumps and damage and typically comes in aluminium or plastic.

Aluminium extrusion is most popular, but other finishes and colours are also available.

Flight case extrusion can be pre-punched with fixing holes and can also come in various configurations and shapes to fit a large range of case uses and functions, such as double angle extrusion, divider extrusion (if you want to add dividing panels within your case to create multiple compartments), u channel extrusion and more.

Corners

Flight case corners are essential to protect cases from damage, especially as impact points on most cases are the corners.

Corners are most commonly made from heavy-duty steel but also come in plastic.

Ball corners provide greater impact protection, but case corners come in a large range of sizes and shapes.

Handles

Easy transportation and handling is essential for flight cases and road cases. Handles are the best way ensure your case is efficiently moved around whether that is rolling or lifting.

There are many types of flight case handles designed for different uses; recessed handles that sit within a cutout with a low profile so they are better protected against knocks and scrapes, surface handles and strap handles which are commonly used for smaller cases such as briefcases or guitar cases, pull out handles which are ideal for heavier trunks like suitcases and corner handles for grip on the corner/edge of the case.

Latches

Latches allow you to open and close the lid or door on a flight case.

Flight case latches come in a range of sizes and styles and are available with locking mechanisms or padlock brackets for extra security.

Recessed latches sit within a cutout in the case boards and are sat within the dish to keep the latch mechanism protected during transportation. Other latches include surface latches, slam latches, overlatches and smaller briefcase/drawer latches.

Castors

Castors or wheels are essential for manoeuvring a flight case, especially for those designed to house heavier items. Castors or wheels used on flight cases are designed with 360 degree swivel for even better mobility.

Flight case castors are made from durable materials such as steel or zinc with rubber wheels.

Castors can come in various sizes and are available with or without brakes. Auto aligning castors coupled with castor dishes are also a popular choice as they make stacking flight cases quick and easy.

In most circumstances, castors are fitted to the underside of the bottom of the case, but you can fit castors on the corner of a case using special edge/corner castors.

Dishes

Flight case dishes, usually made from robust steel or plastic, have a large range of uses.

For professional audio and AV cases, dishes would likely be punched with connector cutouts or include cable feedthrough dishes so you can plug in equipment without having to open the case (ideal for things like playback audio rigs).

Dishes are also used for labelling and identifying case contents and vented dishes are used to improve airflow and cooling.

Feet and castor dishes allow for cases to be stacked on top of each other.

Hinges

Just like hinges on a door in your house, hinges on a flight case enable you to open access doors or lids.

Flight case hinges need to be durable and so are made from materials like steel.

Lift-off hinges allow you to open and then completely detach the lid or part from the case, where as piano and standard hinges keep the lid or part attached to the case.

Lid stays are a clever type of hinge that keep the hinge open at a certain degree/angle for added safety.

Foam

Foam and carpet ensure the contents of the case are protected by essentially creating a cushion that surrounds and pads the item or items inside the case.

Flight case foam comes in various thicknesses and materials. Case foam is usually cut using a CNC machine to provide the perfect shape for the item being transported in the case. A snug fit ensures that the item cannot move around during transportation.

Carpets provide a soft lining inside a case and also create a polished and professional end product. Carpets can come in lots of different materials and colours depending on your needs.

Fasteners

There are many different types of fixings and fasteners available for case builders, the likes of which will depend on many factors such as materials being used, what the case is being used for and what hardware is being fitted.

Most commonly, flight cases are built using aluminium or steel rivets. Rivets can be installed manually, but the most popular way is using a professional pneumatic tool called a rivet gun or rivet tool.

Other fixtures and fittings that may be needed for a flight case include machine screws, wood screws, t-nuts and washers.

Discover the Penn Elcom range of Flight Case Hardware